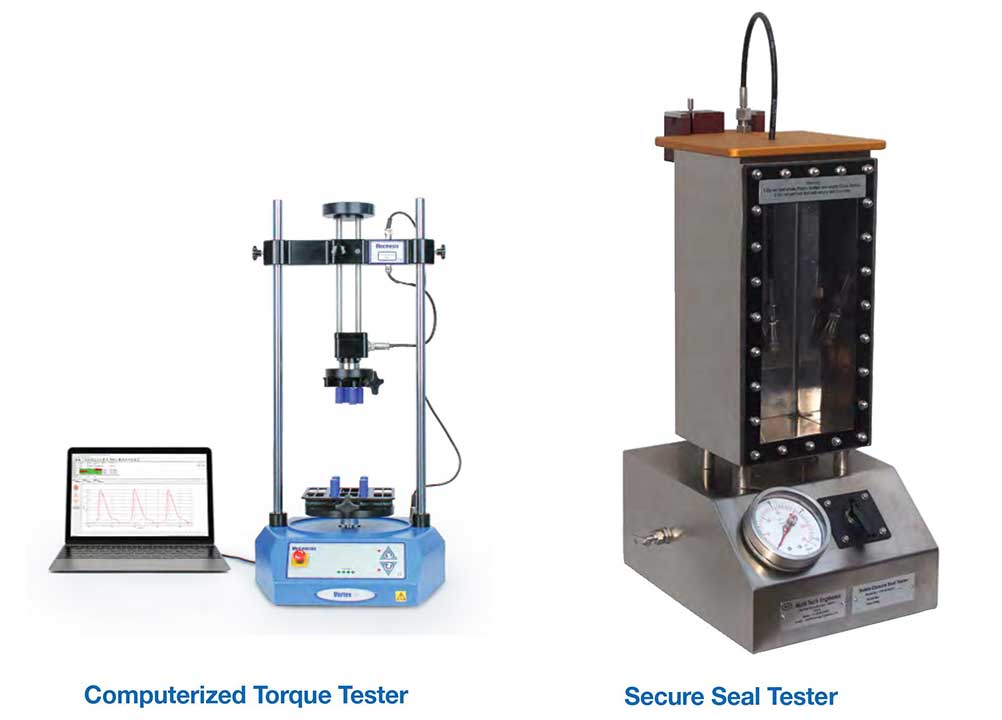

Technical service at its best

All our production sites guarantee a competent technical customer service, ensuring highest application efficiency of our closures on our clients’ lines. Based on our extensive know-how, we help our customers through the safe application.

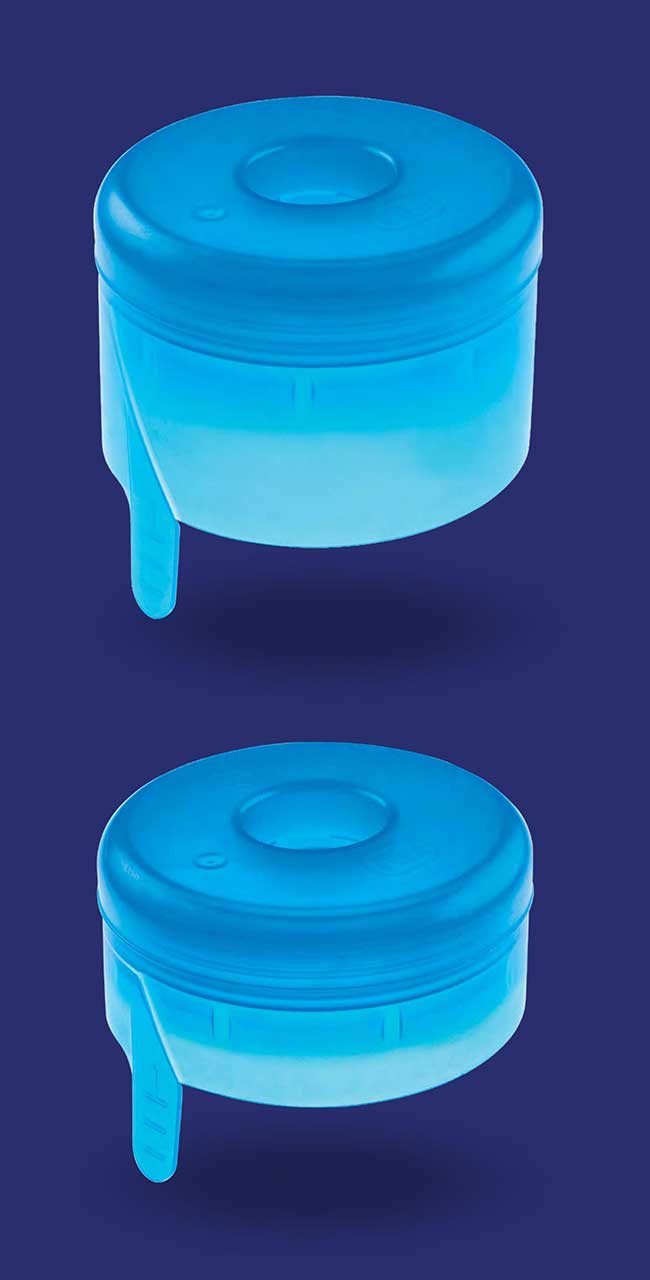

5 Gallon Cap Features

- Suitable for both Extrusion and Preform blow PC/PET bottle 55mm neck finishes

- Easy center opening on cooler dispensers

- Environment friendly Earth Cap with OXO-BIO degradable additives – GREEN CAP

- Variety of CAP colors depending on customer requirements

- Customized heat applied non adhesive easy peel labelling technology

- High quality European standard hot runner fully automatic moulds

- Certificate of Analysis & Conformity with each delivery

- Complies with BRCGS/HACCP and ISO 9001:2015 regulations

- Relevant FDA and EC Regulations

- Raw materials are of High quality and meet all standard

- 100% virgin raw materials used for all products

- All Caps are treated with extensive UV

- CAPS are tested at regular intervals using micro biological analysis

- In-Line high speed assembly machine for Foam Liner and labels with vision inspection cameras

| Types of Cap | Mono Cap | Short Mono Cap | Flat Mono Cap |

|---|---|---|---|

| Unit | mm | mm | mm |

| Height (Skirt + Tail) | 54.50 | 43.00 | 54.50 |

| Height (Skirt) | 38.02 | 26.50 | 38.01 |

| Outer Ø | 57.20 | 57.30 | 57.00 |

| Inner Ø | 54.20 | 54.20 | 55.00 |